Kiyokuni’s soft tooling capabilities allow us the flexibility in our manufacturing techniques to approach your unique project requirements with proven solutions.

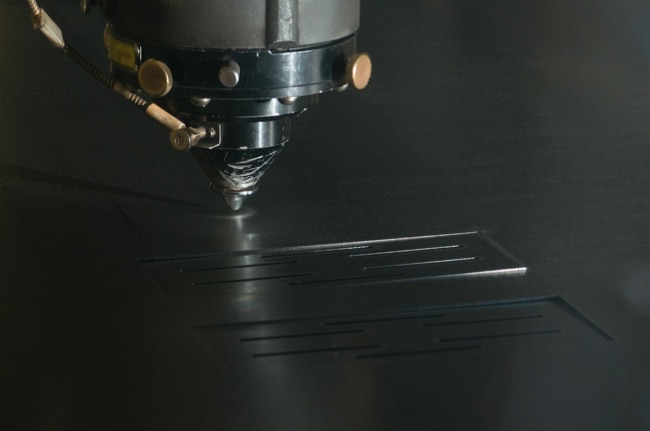

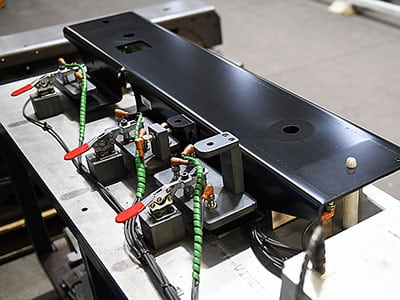

Soft tooling consists of using a range of machines to form your end product, as opposed to creating custom hard tools for pressing. At Kiyokuni, we utilise in-house laser cutting and bending machinery to create pressed products in a cost- and time-efficient manner.

The Latest Technology

Our in-house soft tooling capabilities include laser cutting, bending parts on Press Brakes, and producing complex punched parts on a NC Turret Press.

Our investments into the latest technology enables us to work with precision machinery, producing consistently accurate pressed parts within tight tolerances.

Our soft tooling is also available for prototypes, offering a quick and cost-efficient method which allows for any necessary changes to take place prior to full production.

Soft Tooling vs Hard Tooling

If you’re unsure on the type of tooling your project requires, our experienced team of engineers can advise you during initial consultations.

Choosing the right manufacturing process from the start ensures increased product quality, and the delivery of your product on-time and on-budget.

Hard tooling refers to the use of press machinery and custom steel tools or dies to make a part. Whereas, soft tooling makes use of different machines to produce a part, without the need for tool making. Whilst this makes soft tooling a cost-efficient manufacturing method for small volumes or one-off batches, hard tooling can be more practical for larger projects.

For high volume projects and our hard tooling capabilities, see Press Tooling.

Gallery

Click below to view our gallery:

Speak to the experts

Are you at a project blueprint stage and want a quote for our services?