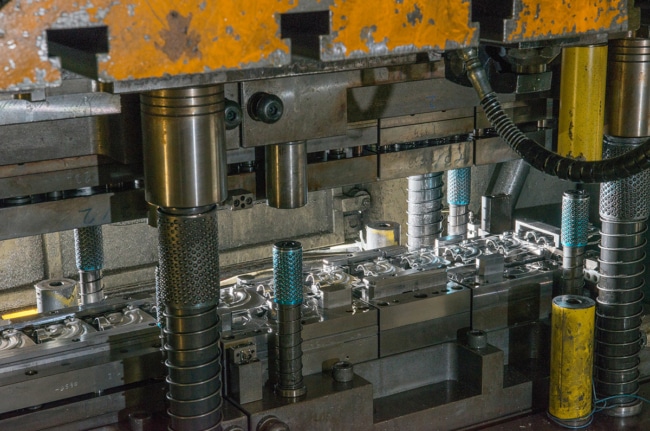

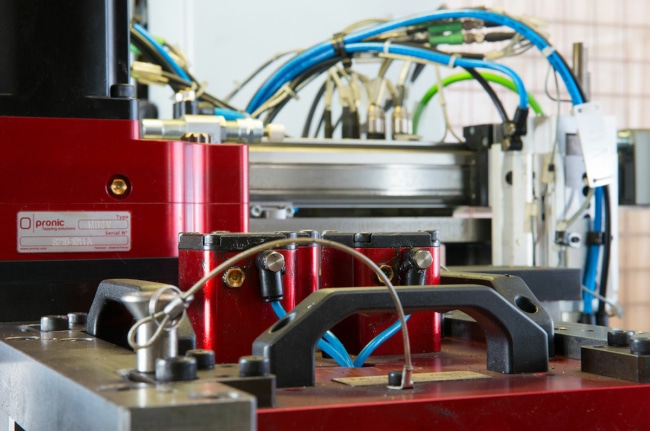

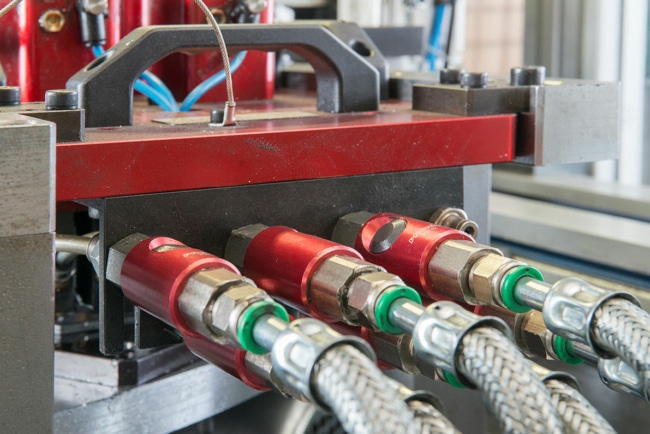

Kiyokuni’s progression presswork capabilities enable us to carry out multistage operations in one tool, for an automated and efficient production process that can produce finished parts from coil material in one process.

We can create all types of pressed components on our progression machines, with numerous production methods achievable. This includes: sizing, burring, embossing, forming, folding, cutting, and in-tool tapping. Led by our expert team, we can advise you on the most appropriate path to production for your unique specifications.

Increased Capabilities, Reduced Time

Progression presswork involves working multiple forms on one machine and on one piece of metal. The component is gradually formed by passing sheet metal through a number of stages within the tool until the final part is produced.

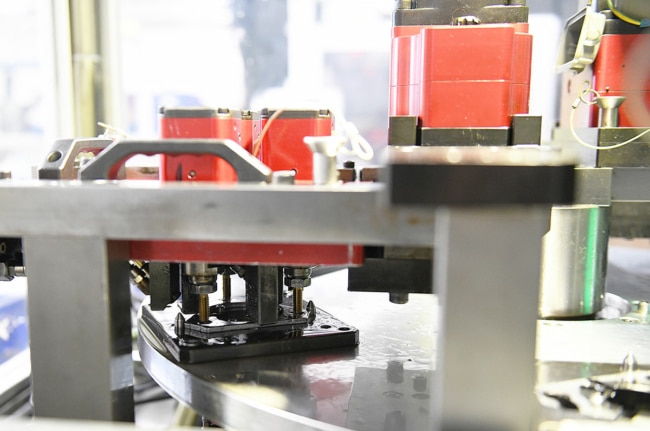

This production method is suitable for smaller, less intricate metal pressings, which can be created at higher speeds for a cost-efficient process.

Kiyokuni’s progression production machines can run at speeds of up to 100 strokes per minute – greatly reducing production time on demanding projects.

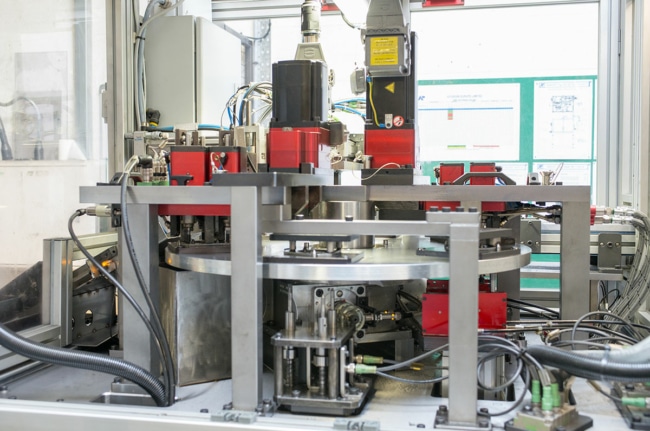

Kiyokuni’s extensive plant list for progression work allows us to cater to a variety of projects; our machinery ranges from 110 ton to 400 ton.

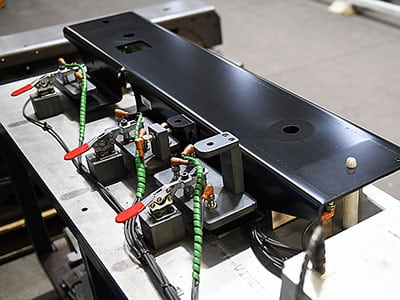

Our progression machinery includes:

- 1 x 400 ton Aida Servo Progression Press

- 1 x 300 ton Aida PMX Progression Press

- 1 x 300 ton Aida Progression Press

- 1 x 250 ton Amada Progression Press

- 1 x 250 ton Chin Fong Progression Press

- 1 x 160 ton Aida Progression Press

- 1 x 110 ton Aida Progression Press

Gallery

Click below to view our gallery:

Speak to the experts

Are you at a project blueprint stage and want a quote for our services?