We have a range of quality presses with which to complete all types of steel presswork, giving us the flexibility to meet the specifications of your project in the most efficient and calculated manner.

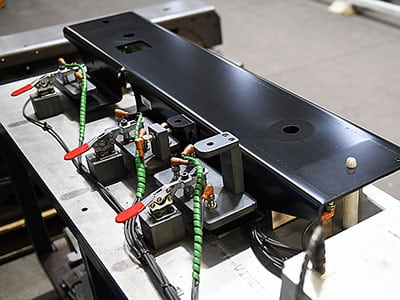

Our hard tooling presswork is suitable for projects requiring multiple production cycles or high-volume batches. We use bespoke tooling, available through Kiyokuni, for this. We also offer soft tooling presswork where this is more appropriate.

From intricate, low volume pressings through to high volume batches of 500,000 parts per month, Kiyokuni’s extensive pressing capabilities are sure to meet your requirements with quality production and customer service.

Our Presses

Our press capacity ranges from 25 tonne hydraulic presses to 260 tonne mechanical presses. Included within this, we also hold Servo presses. This range of machinery ensures we can form the right solution for the needs of your project and industry.

Expertise in handling multi-stage techniques and reducing changeover periods allows us to increase the efficiency of our work alongside this, and means we can quickly respond to new projects or changing requirements.

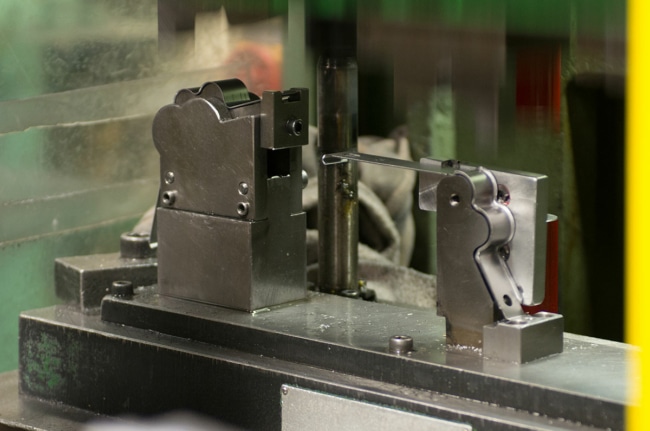

Press Tooling Needs

Kiyokuni can provide custom tooling based on project specifications for the production of presswork. Alternatively, our customers are welcome to use their own tooling.

Supported by fully-approved subcontractors, Kiyokuni provides competitively-priced, quality tooling, including blanking and piercing tools, forming and progression tooling.

For projects with multiple production runs, we maintain our tooling through a Total Productive Maintenance (TPM) programme to pre-agreed levels or volume driven programmes for preventative maintenance.

Our TPM plans include regrinding, cleaning, polishing and more to prevent the wear and tear of tooling, as well as premature replacements.

Press repair machinery:

- 1 x Sodick ALC600G Wire Cutting Machine (max working capacity 600 x 400 x 250)

- 1 x XYZ 2 axis CNC Milling Machine SMX SLV

- 1 x XYZ 3 axis CNC Milling Machine SMX4000

- 1 x Milling Machine

- 4 x Surface Grinding Machine

- 1 x Conventional Lathe

- 1 x Bandsaw

- 1 x Radial Drill

- 2 x Solidedge 3D Cad software

- 2 x Amada VPSS (for NCT)

- 1 x Metalsoft CAD (for NCT)

Steel Metal Pressing Gallery

Click below to view our gallery:

Speak to the experts

Are you at a project blueprint stage and want a quote for our services?