Kiyokuni’s metal pressing capacity includes working with stainless steel. We handle both 304 grade and 316 grade stainless in-house, although we can work with all grades to account for customer requirements.

Pressings are manufactured from sheet or blanks of up to 8mm thick or from coil up to 4mm thick and 800mm wide; Kiyokuni can manufacture all types, sizes, and complexities of pressings within this capacity.

Finishes include high polish finish for pressings that are to be used within highly visible applications, as well as copper plating for increased heat conductivity of the part.

Applications for Stainless Steel Pressings

Our stainless steel pressings are suitable for projects where enhanced appearance or corrosion-resistance takes precedent.

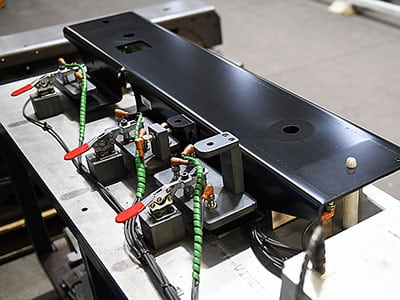

At Kiyokuni Europe, we manufacture stainless steel parts for the automotive industry and for air conditioning systems, where they are optimised for performance within wet and damp environments. However, we have extensive experience providing a range of pressings for a number of industries and applications and welcome all project types.

Our Capabilities

We can manufacture pressings using hard tooling on a wide range of equipment ranging from 25 Ton hydraulic presses, 80 Ton to 200 Ton hand operated mechanical presses and coil fed progression presses ranging from 110 Ton to 400 Tons.

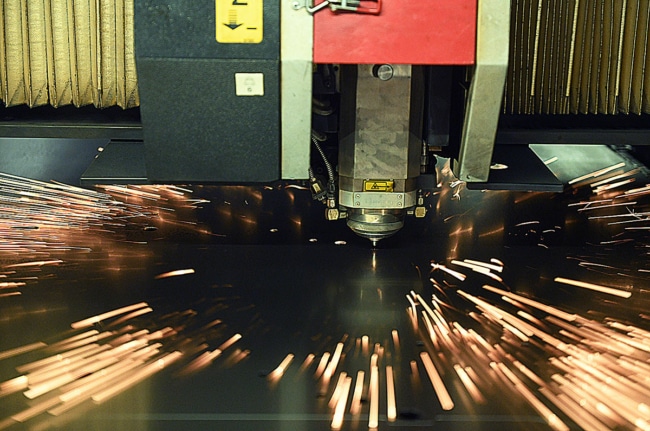

For low volume stainless steel pressings we can offer soft tooling solutions using a Laser, NCT Turret Punch and Press Brakes which can either reduce or eliminate the need for hard tooling, reducing the cost of producing parts substantially.

Gallery

Click below to view our gallery:

Speak to the experts

Are you at a project blueprint stage and want a quote for our services?